What is MEKO?

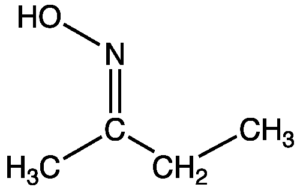

What is MEKO? MEKO stands for Methylethyl Ketone Oxime which is an organic compound with the formula C2H5C(NOH)CH3.

PHYSICAL PROPERTIES:

Appearance: colourless liquid

Density: 0.923 g/cm3

Melting point: −15 °C (5 °F; 258 K)

Boiling point: 152 °C (306 °F; 425 K)

SYNONYMS

SYNONYMS

- MEK-oxime

- Butanone oxime

- Methyl ethyl ketone oxime

- 2-BUTANONE OXIME

- Ethyl methyl ketoxime

- USAF EK-906

- Ethyl-methylketonoxim

- UNII-51YGE935U9

- 2-Butanone, oxime

- Methyl ethyl ketoxime

- 51YGE935U9

- Troykyd anti-skin B

- Skino #2

- USAF AM-3

- WLN: QNUY2&1

- Ethyl-methylketonoxim [Czech]

- CCRIS 1382

- 96-29-7

- NSC 442

- EINECS 202-496-6

- BRN 1698241

CHEMICAL REACTIVITY

Reactive Group: –

- Oximes

Reactivity Alerts: –

- Highly Flammable

- Decomposes at Elevated Temperatures (<120 deg. C)

Air and Water Reactions:-

- Highly flammable.

- Water

Reactivity Profile:-

- MEKO is sensitive to heat.

- Has exploded at least twice when heated in the presence of acidic impurities.

- Reacts with oxidizing agents.

- Mixtures with strong acids may explode.

- Reacts with sulfuric acid to form an explosive product.

APPLICATIONS

- Adhesives and sealant chemicals

- Paint additives and coating additives not described by other categories

- Solvents (which become part of product formulation or mixture

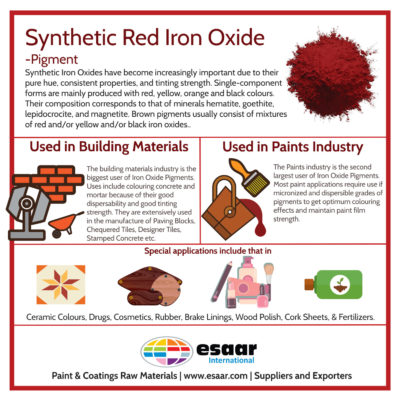

IN PAINT INDUSTRY

MEKO, as it is called in the paint industry, is used to suppress “skinning” of paints: the formation of a skin on paint before it is used, hence is a popular anti-skinning agent.

Skinning is the biggest nuisance in protective coatings. Skinning causes the avoidable waste of a costly coating material.

Paint containers are not always filled to the brim. So air present in a void reacts with the paint, thereby causing oxidation and polymerization of the coating at the air/paint interface. This results in formation of a solid skin during storage.

The lost of paint due to skinning is estimated to be as much as 3 to 5%. This not only worries the consumers but also the manufacturers when it comes to filling of small containers. The minute doze of an effective anti-skinning agent can alleviate the difficulty of skinning.

what is MEKO: Chemical property of MEKO which is useful in paint industry :-

MEKO functions by binding the drying agents, metal salts that catalyze the oxidative crosslinking of drying oils.

Once the paint is applied to a surface, MEKO evaporates, thereby allowing the drying process to proceed. Other antiskinning agents have been used, including phenol-based antioxidants, but these tend to yellow the paint.

HEALTH HAZARDS:-

- Symptoms of exposure to this compound may include slight eye and skin irritation.

- If gets absorbed through the skin can cause harmful effects on the blood and nervous system.

- If inhaled in greater amounts can give rise to symptoms such as wheezing, coughing, shortness of breath, or burning in the mouth, throat, or chest may also develop.

- It may interfere with alcohol metabolism resulting in the formation of acetaldehyde, blotchy red marks, red eyes, tiredness and visible veins.

FIRE HAZARDS:-

- This chemical is combustible.

- Fires involving this material can be controlled with a dry chemical, carbon dioxide or Halon A water spray may also be used.

ENVIRONMENTAL HAZARDS:-

- MEKO has minimal potential to accumulate in the bodies of humans or animals. It is readily biodegradable and will not persist in the environment.

- When heated to decomposition it emits toxic fumes of carbon monoxide, carbon dioxide and nitrogen oxides.

Find our TDS on our MEKO product page: Click Here

Leave a Reply