What are Inorganic Pigments in Paints?

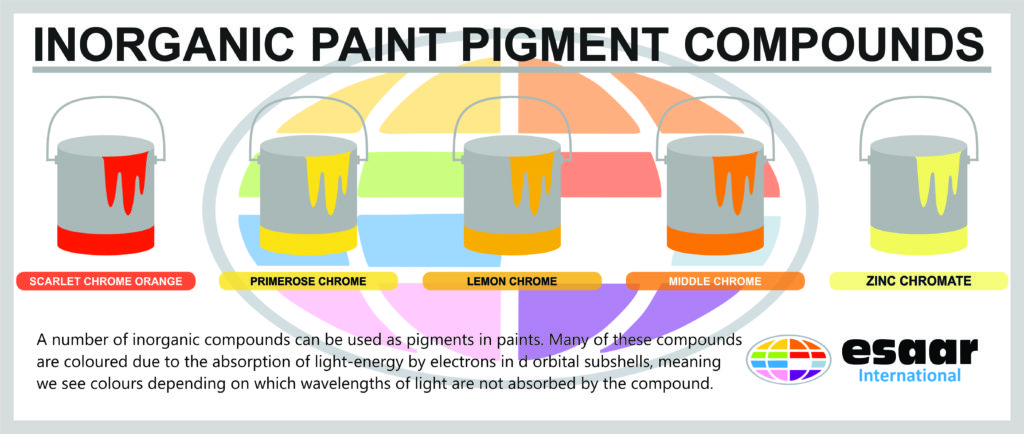

Inorganic pigments are crystals of metal compounds (often oxides). Transition metals have their bonding electrons in the d orbitals – when the metal is bonded to groups of atoms. This can cause the d orbitals to ‘split’ into two levels of energy. The electrons in these orbitals can then absorb energy to move between the two levels – the energy gap between the levels determines the wavelength of light absorbed. As not all of the light hitting the compound is reflected, this means we perceive them to be coloured.

Paints & coatings are produced primarily for the automotive, industrial and coil coatings markets. Exterior durability is the main focus; therefore the combination of colour and performance is key when determining pigment selection.

In today’s world of ever-increasing expectations, the surface coater is facing a tough challenge. The ability to “think smart” has to be of primary importance in the race to differentiate oneself, while seeking to maximize profitability.

The Role of Pigments in Protective Paints:

The pigment component in any formulation can either enhance or degrade the overall performance of the protective coloured coating. In highly alkaline cement-based and silicate coatings, the chemical resistance of the pigment is crucial. In camouflage applications and substrates that cannot tolerate heat build-up, such as PVC extrusions, vinyl sidings and some coil coatings, the functionality of the pigment is the determining factor. Infrared reflective pigments are needed when dark, coloured coatings are required that minimize the heat retained in the protective coating. Increasingly, specifiers are looking for pigment suppliers that can correlate the relationship between pigment functionality and performance so that the end result enhances the durability of the finished coating.

Demanding Processes

The inherent thermal and chemical stability of mixed metal oxide inorganic pigments offers a unique coloring solution to formulators, where high processing temperatures are involved. Ease of dispersibility, combined with stability to flocculation and gelation, are favorable characteristics influencing inorganic pigment selection.

Demanding Binder Systems

Inorganic pigments are compatible with pH-dependent systems, such as acid-catalyzed coatings, highly alkaline silicate masonry paints and cement slurries, and engineering polymers that can be highly reactive (polyamides and some co-polymers).

Binder Degradation

Most polymeric binders are inherently unstable and will degrade when aged in the presence of moisture, oxygen, and ultraviolet (UV) radiation. UV acts as the initiator to the photocatalytic cycle, as shown in Figure 1.

Correct pigment selection is key to either enhancing or de-stabilizing the binder.

To view our full inorganic chromes catalog please click on the link below:

Leave a Reply